Hop trade and primary agricultural production

We specialize in growing Czech Saaz Hops (Žatecký poloranný červeňák), cereals and rapeseed.

About us

The company’s headquarters are located in Holedeč, 7 km from the famous hop town of Saaz (Žatec).

We have been working with the company Joh. Barth & Sohn since 1991. This cooperation covers comprehensive services and includes the closing of purchase contracts with farmers from Czech Republic and Slovakia, organization of training courses for the protection of hops, preparation of financial advances for farmers, inspection and advisory services for farmers during growing season, organization of hop collection from farmers, transport to storage, sampling and analysis of hops, evaluation, examination of hops, the transport of hops to Joh. Barth & Sohn and the billing of individual farmers.

Emil Bureš HOPSERVIS s.r.o. also focuses on primary agricultural production. The company has two centers - Postoloprty and Holedeč. At the Postoloprty center, we cultivate 86 ha of hop fields. At the Holedeč center, we cultivate 70 ha of hop fields and 430 ha of arable land, where we grow cereals and rapeseed. We practice thoughtful farming, keeping the environment in mind.

Take a look at our promotional video.

Services for farmers

Tip: If you are interested in any of our services, please contact us using the online form or by phone.

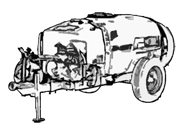

Sprayers

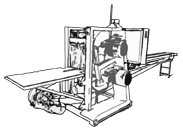

Packing Machines

Consulting

Process of cultivation and harvest of hops

Tip: By clicking “read more”, you can read up on all of the steps of the hop treatment process before the hops are actually sold.

1. The importance of growing hops

Hops are important industrial crops, grown for the harvest of hop cones, which are an essential ingredient for beer production.

read more2. Land preparation and planting hops

A year before the hops are planted, the land is fertilized with lime, organic and industrial fertilizers and the soil is thoroughly tilled.

read more3. Autumn work

Clearing hop fields after the harvest, fertilizing hop fields, autumn tillage, thorough ploughing in between rows and planting in sparse parts of the hop field.

read more4. Spring work

Dragging hop fields in combination with a spring application of mineral fertilizers, mechanized cutting, implementing hop poles and wires, and planting the hops.

read more5. Summer work

Cultivating the hop field, summer application of herbicides, tending to bent plants, hanging fallen hop plants, hop protection.

read more6. Harvesting the hops

The hop harvest takes place after hops have reached technical maturity - the cones are closed, supple when pressed, are of a yellow-green colour with a natural shine and have high lupulin content.

read more7. Drying the hops

Stripped hops can breathe easily and generate heat and moisture. Due to the risk of spoilage, hops must be quickly transported to the drying room.

read more8. Treatment of dried hop cones

Dried hop cones are brittle, they are susceptible to damage and crumbling, and cannot be handled further. It is therefore necessary to adjust humidity levels.

read more9. Quality assessment

Baled and labeled hops are transported to the central warehouse where sampling and verification is carried

out.